E-plopper XL oliebollen machine

The E-plopper XL oil ball dispenser is the only one of its kind with a fully electric drive. Compressors, high energy consumption, noise pollution and tripping hazards around your fryer are a thing of the past.

With its hopper capacity of 100 liters and a speed of up to 360 oil balls per minute, this model is the perfect equipment for the professional and industrial oil ball baker.

The E-plopper XL comes very complete, with Elevator cart for easy filling and moving of the machine,Adapter to use directly from the socket when the battery is empty, XLbattery to dose up to 50,000 oil balls completely wireless. Minimes For nice round mini oliebollen or Smoutebollen. Delivery to your location & 3 years warranty on all parts.

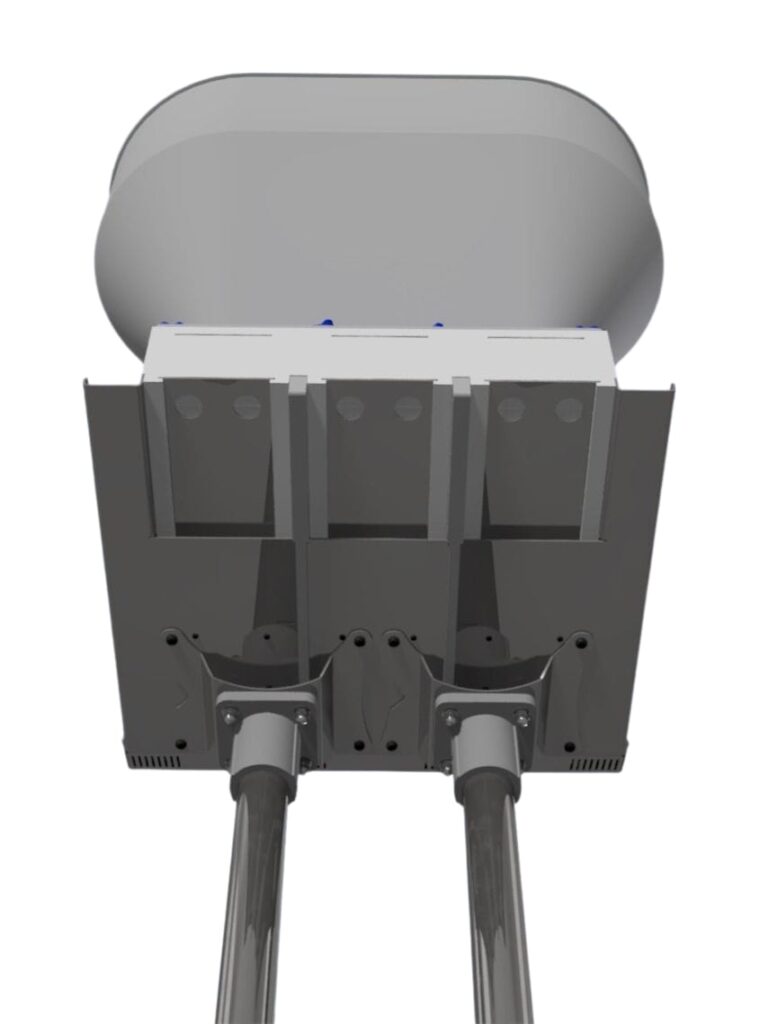

Oil balls,Currant balls,Smoutebollen,kwarkbollen, doughballs with or without filling it is no problem for the E-plopper XL. With the 3x 280cc piston you dose 6 oliebollen with a weight between 15 and 110 grams in 1 dosing motion. You can also dose with the included Minimes 9 mini oil balls / Smoutebollen simultaneously to a speed of 540 balls per minute.

The digital display is easy to read, even in the event of a malfunction, the problem is immediately displayed in readable text. No menus or unclear settings, all information can be found in 1 overview, Number, Speed and size can be set directly via the keypad.

With its stainless steel construction, very compact housing and numerous functionalities as shown below, this is the machine for every professional baker.

Technical specifications

| Order details: | |

| Price | |

| Delivery | 12 weeks, on order only. |

| Down payment on order | 60% |

| General implementation: | |

| Implementation | STAINLESS STEEL |

| Funnel content | 100 Liter |

| Nutrition | 230VAC 1.5A |

| Width of dosing head | 500 mm |

| Weight | 140 kg |

| Settings: | |

| Number | Unlimited or counting to 998 |

| Volume | 3x 10 – 280cc divided into 6 spheres |

| Speed | 3 – 360 oil balls per minute |

| Features: | |

| 100% Electric | No compressor needs to be connected, a power outlet is sufficient. Also, the battery offers the ability to dose up to 50,000 oil balls without a cord across the floor. |

| Day counter | Resettable total counter that adds up doses |

| Total counter | Non-resettable total counter that adds up doses |

| Countdown | Display of remaining oil balls during dosing |

| Auto stop | Stop automatically when set number of bulbs is dosed |

| Single button | Performs 1 single dose when the button is operated |

| Emergency Stop | Quick and immediate double shutdown in the event of danger |

| Safety monitoring | At startup, the machine checks all safety devices |

| Battery indicator | Displays the remaining battery content. |

| Internal temperature control | Machine controls its own temperature and automatically controls ventilation. |

| Control LEDs | Internal LEDs indicate status of the machine in case of failure. |

| External start | Have your external production line or a sensor give the start signal |

| External Emergency Stop | Let your remote production line safely stop the machine |

| Dosing chamber dismountable | The dosing chamber is removable for easy cleaning of the inside. |

| Unique serial number | Each machine has a unique digital serial number, which allows the history and original owner of the machine to be traced. |

| Rail and cart assembly | It comes standard with 4xM10 bolt holes on the bottom for mounting on a rail or undercarriage. |

| Energy conscious | During dispensing, it consumes only 1.5 amperes of current, which is a factor of 10 lower than a compressor for pneumatic dispensers. |

| Stiller | No more humming compressor, and the machine also makes less noise because there is no need to blow off compressed air. |

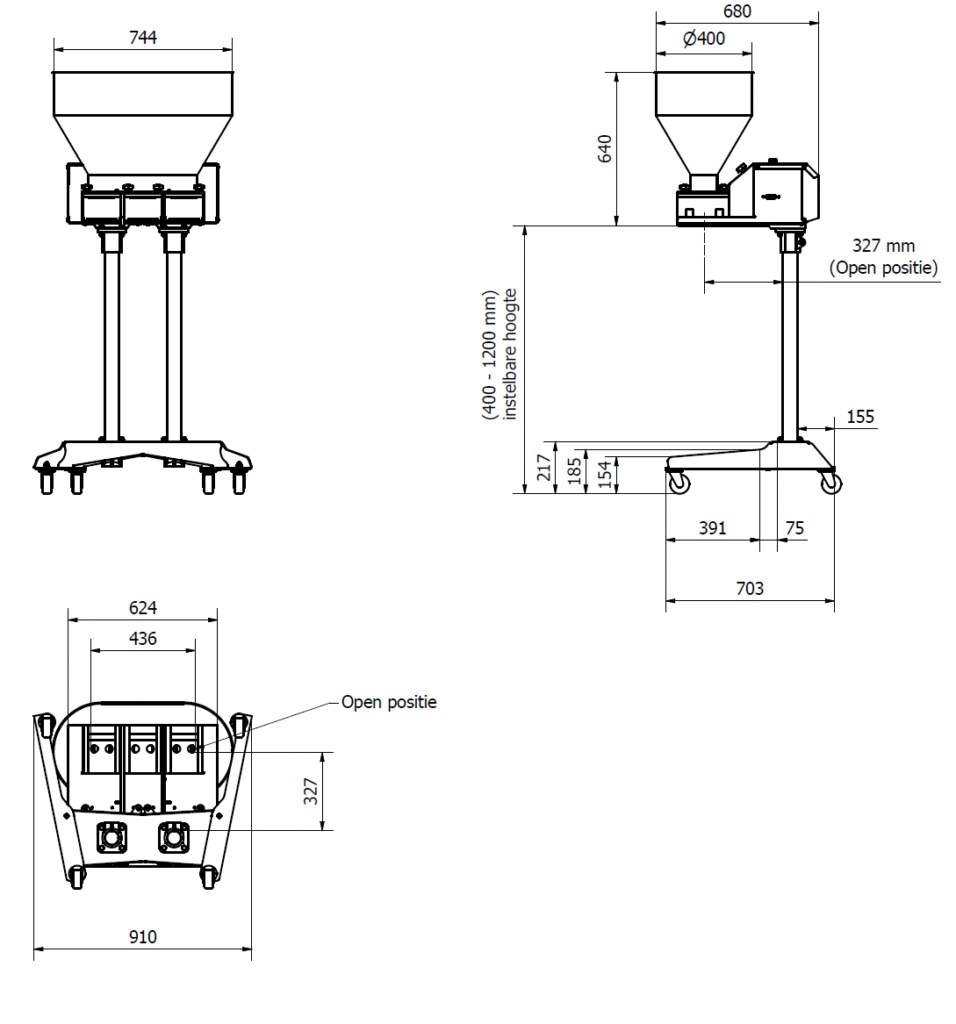

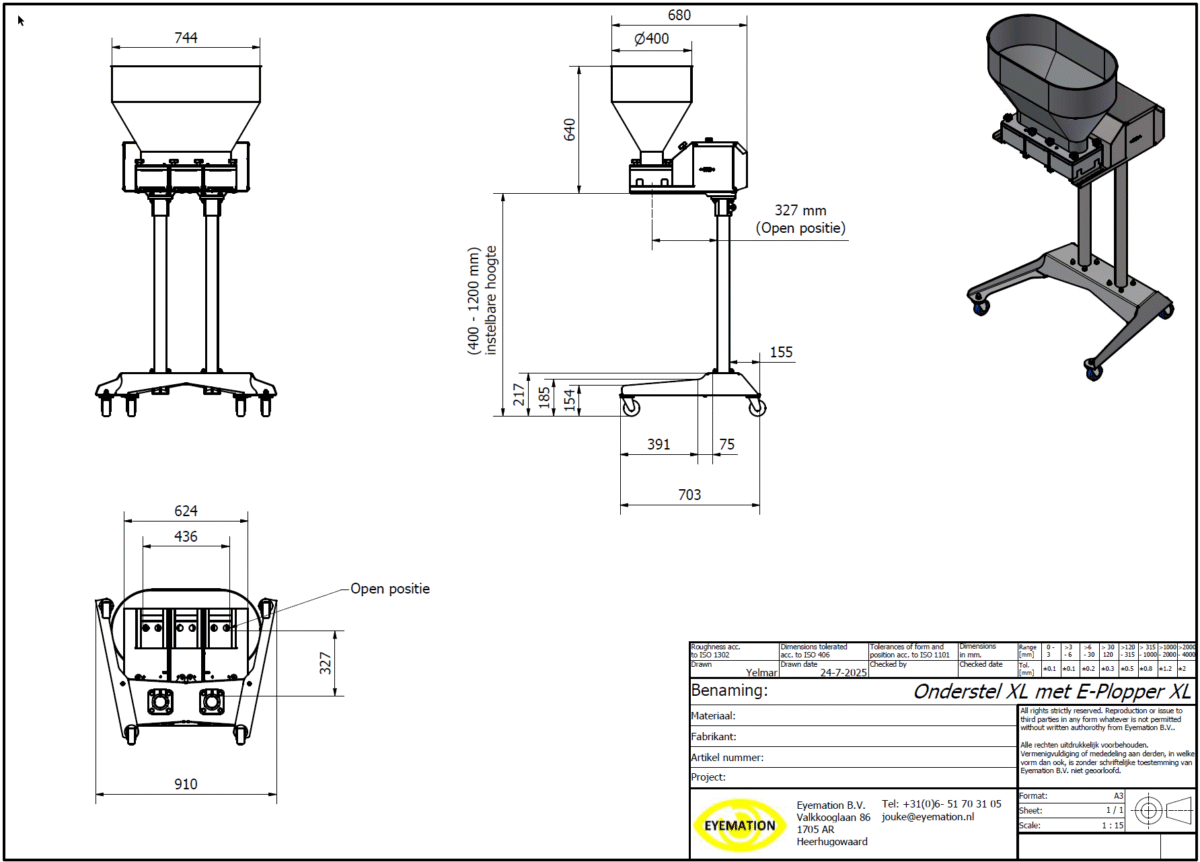

Technical drawing